Use our patented hydraulic cell compression, which offers many advantages over mechanical compression.

The process can be used for fuel cells as well as electrolysis cells. In this process a cell is surrounded by a hydraulic medium, this medium is not in direct contact with the cell materials. The medium can be pressurized and transmits this pressure to the cell and the cell materials (current distributors, membranes, etc.) inserted in the medium.

This results in several advantages

- Fast and precise temperature management (cooling and heating) to set the temperature and maintain a constant operating point.

- Homogeneous cell compression of the active materials (flow distributors, membranes, etc.).

- Quick and easy change of cell materials.

- Scalable cell sizes can be implemented.

- High gas outlet pressures possible.

- High reproducibility due to reproducible pressing and constant temperature maintenance.

- Longer lifetime of active materials due to homogeneous pressing and temperature control.

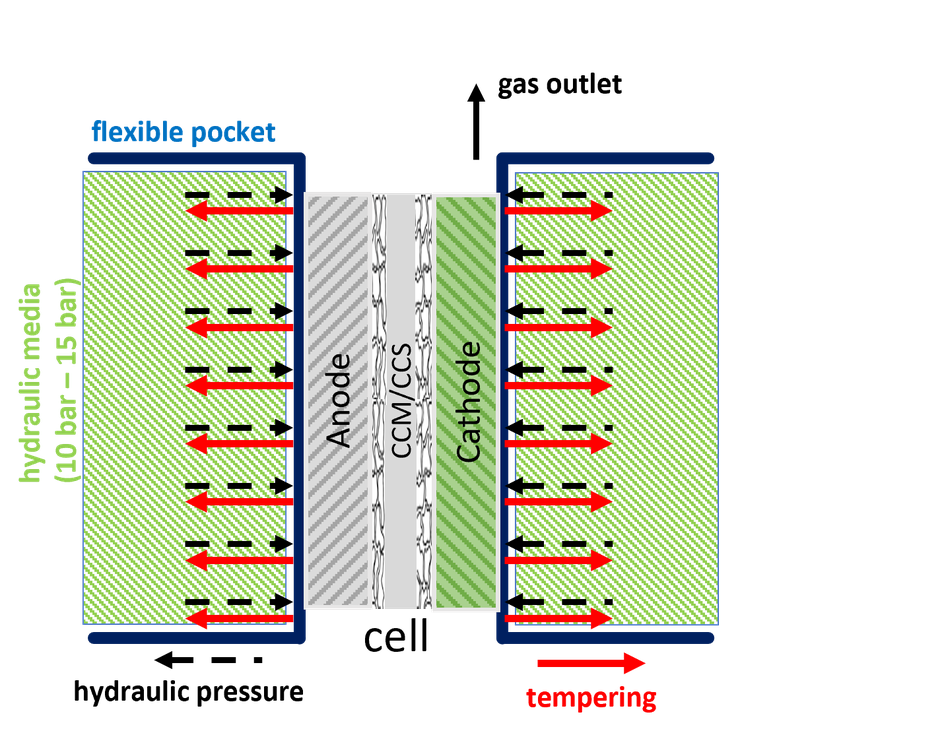

Shown above is a schematic diagram of a hydraulically pressed electrolytic cell. The cell consists of an anode, cathode and an inserted CCM/CCS. The cell is surrounded by a flexible pocket, which separates the hydraulic medium (usually a thermal oil) from the cell.

Pressure can be applied to the cell via the hydraulic medium. The hydraulic pressure or compression of the cell provides the seal of the cell to the outside. The resulting compression is very homogeneous, as it is known that a constant pressure builds up in fluids. The cells can be selectively heated or cooled via the thermal oil. In this process, the thermal oil is brought as close as possible to the active materials or the membrane.

This process also allows high gas outlet pressures to be realized. Care must be taken to ensure that the pressure in the hydraulic medium is greater than the gas outlet pressure in order to ensure compression and the tightness of the cell. Stacks with 100 bar hydrogen outlet pressure have already been realized with this process.

Below you can see the influence of the hydraulic pressure on the cell voltage, for a stack consisting of five cells and an applied current of 2 A/cm² for an active area of 25 cm² each.